How to choose injection packer?

When carrying out grouting waterproofing construction, the injection packer has become an indispensable tool and accessory. Efficient, stable and multifunctional grout injection packer can not only save a lot of time, but also provide more accurate work results. Therefore, choosing a injection packer with excellent performance has become an urgent need for waterproofing construction.

So, which brand of injection packer is easy to use and good quality? When choosing, you should not only pay attention to the brand's popularity, but also judge its performance in combination with the specific parameters of the product. Length, diameter, rubber tube and grease nipple are all key factors affecting the use of injection packer. Thus, how to find the one that suits you best among these choices?

In the following content, we will explore in depth the parameters that need to be paid attention to when purchasing injection packer. This will help everyone make rational choices, and at the same time answer the question of which brands of injection packer on the market have good quality and high cost performance. Are you ready to learn how to choose a injection packer? Let's continue to uncover the answer.

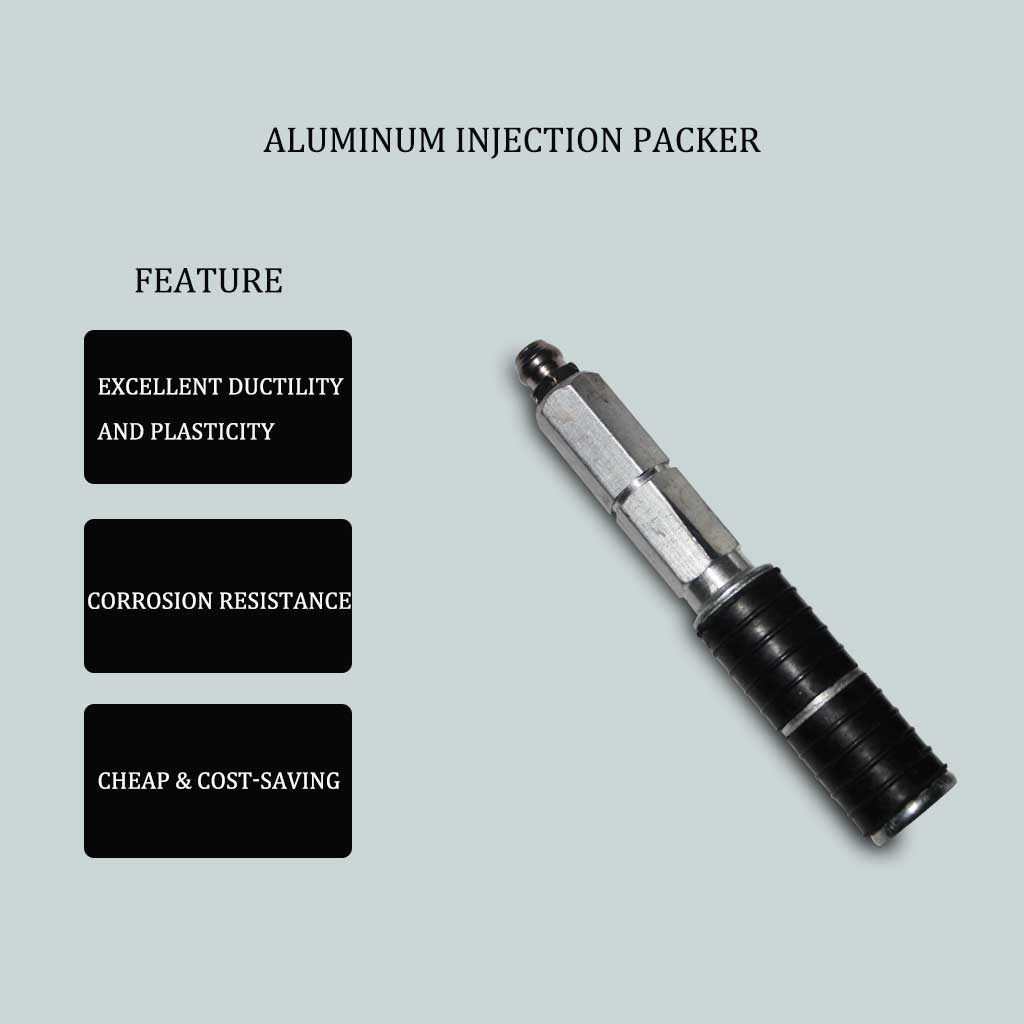

Choose aluminum injection packers

The aluminum injection packer uses aluminum as the raw materia, which has excellent ductility and plasticity. The length can range from 80mm to 1000mm. The commonly used diameters of aluminum injection packer are 10mm and 13mm, which are suitable for a variety of chemical grouting, such as subway tunnels and curtain injection.

Aluminum has good corrosion resistance and is especially suitable for the chemical grouting materials. As chemical grouting materials are generally corrosive, the aluminum tube can allow the slurry to reach the place where it needs to be poured smoothly. It can still remain rust-free for a long time in a highly corrosive epoxy slurry environment, completely solving the industry pain point that the needle is easily corroded by chemical slurry and achieving a water-stopping effect.

The lightweight aluminum injection packer adopts a hexagonal tube structure. By using sleeve clamp allows the rubber expansion to be quickly fixed in the drill hole.The design of one way valve can avoid PU foam leakage and reduce waste. The overall cost of the aluminum injection packer is low, suitable for large-scale waterproofing construction and chemical grouting engineering.

Steel injection packer feature & application

Steel injection packer are superior to aluminum packer in hardness and wear resistance. They can be used for a long time in harsh environments such as moisture and corrosion without being easily damaged. However, the ductility of steel is relatively weaker than that of aluminum. Generally, the tube body is cast and the length is generally controlled at 150mm.

Commonly used steel injection packer are 10*100mm and 13mm*100mm. Steel grout packer have high strength and can withstand large pressure. They are suitable for cracks injection that require high-pressure impact, so that the cracks are filled with slurry during the grouting process, ensuring the stability and reliability of the construction.

In addition to the high-strength tube body, the grease nipple is also an important factor affecting the grouting effect. Choose the appropriate grease nipple for different slurry characteristics. Small grease nipple ball matches low viscosity chemical grouting materials, such as acrylic gel, Polyurethane. Big grease nipple ball matches higher viscosity chemical grouting materials, such as epoxy resin. In the waterproofing engineering, it is better choosing mix using the steel packer and aluminum packer for cost effective.

Why choose button flat head injection packer

Button head injection packer have two model, one is a small flat head fixed model and another large removable head. The diameters are 13mm, 15mm, and 18mm, and the length can range from 110mm to 300mm. It is specially developed for large-flow grouting application, such as building waterstop and tunnel reinforcement.

For small button head packer, the body and grease head fixed together. It is suitable for high-pressure grouting and is matching with oneway valve ball to effectively prevent slurry backflow. The large flat head packer adopts a screw-type split structure. The operator can monitor the slurry flow status in time, reducing material loss compared with traditional metal injection packer

In view of the shortcomings of traditional metal grout packer that are easy to blockage, the flat head needle is specially designed with a large-caliber stop valve ball structure to achieve large-flow grouting and instantaneous stop functions, greatly improving work efficiency.

What is the feature of One Day injection packer

One day injection packer is an upgraded model of the steel packer, with a check valve added to the tail end. The One day injection packer provides a double protection barrier for slurry delivery with double check valves at the head and tail. During grouting injection process, the check valve automatically opens to ensure smooth flow; once grouting stop, the valve quickly closes to completely block the slurry backflow.

In projects with tight construction schedules, one-day injection packer can significantly improve construction efficiency. The average construction period of projects using this packer is shortened by 15%-20%, and the failure rate caused by backflow is reduced, becoming a benchmark technical solution that takes into account both efficiency and safety.

It is precisely because of the efficient construction speed that this packer is called one day injection packer. It can reduce the complexity of construction and is particularly suitable for the rush work needs in the field of building waterproofing.

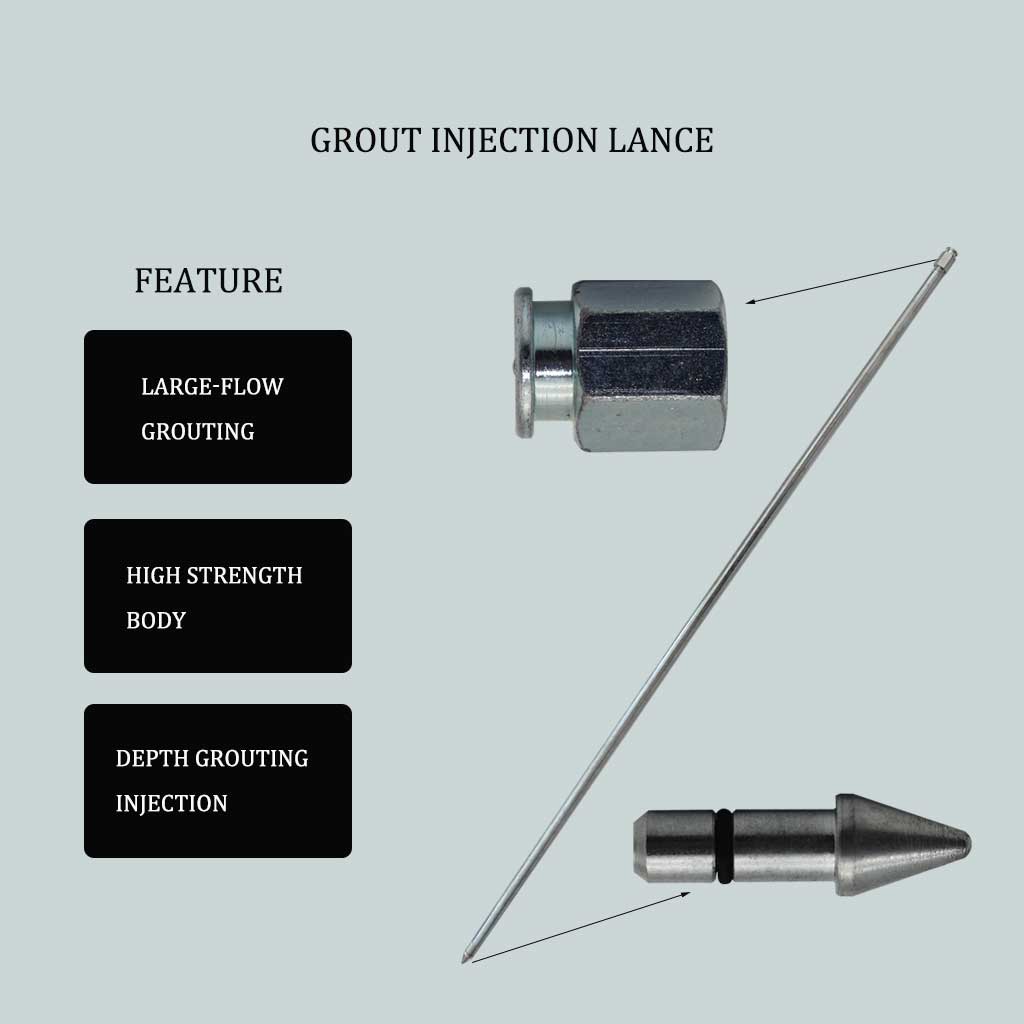

Injection lance for soil stabilization

The ram grout injection lance is an efficient equipment for soil underground stabilization and rock layer repair. It is made of high-quality stainless steel pipe body with high strength characteristics. The product is available in two standard lengths of 1 meter and 2 meters. Through the threaded connection it can be flexibly extended to a depth of several meters, easily applying for deep cracks and loose foundations.

15mm and 18mm are popular model. The inner wall is precisely polished to effectively reduce the flow resistance of the chemical materials and improve the construction efficiency. The standard anti-clogging injection head ensures the high-pressure stable output of materials such as cement slurry and epoxy resin.

The 15mm injection lance is suitable for fine operations such as building pile foundation reinforcement and underground cavity precision grouting, while the 18mm large injection lance is specially optimized for scenes with large flow requirements such as dam anti-seepage and slope stability. For more information, please visit the injection lance page.

Screw packer avoid chemical grouting materials waste

The screw injection packer adopts a split combination structure, consisting of a high-strength grouting tube and an adjustable nut. Through scientific design, the grouting process can be observed in real time to avoid material waste caused by traditional blind injection. In the field of building repair and engineering grouting, the screw injection packer has become the preferred accessory for precise crack grouting with its unique design.

The tube and nut adopt a double-layer galvanizing process, and the corrosion resistance is improved by 5 times. It is suitable for high-humidity environments such as underground projects and coastal facilities.

Screw packer length from 80mm to 500mm, suitable for different depths of grouting cracks. For example, concrete structure crack repair, geotechnical engineering anchor grouting reinforcement, and building protective grouting. The price of the screw needle is relatively expensive, but its reusable characteristics can reduce the overall grouting cost. For more information, welcome to visit screw packer technical page.

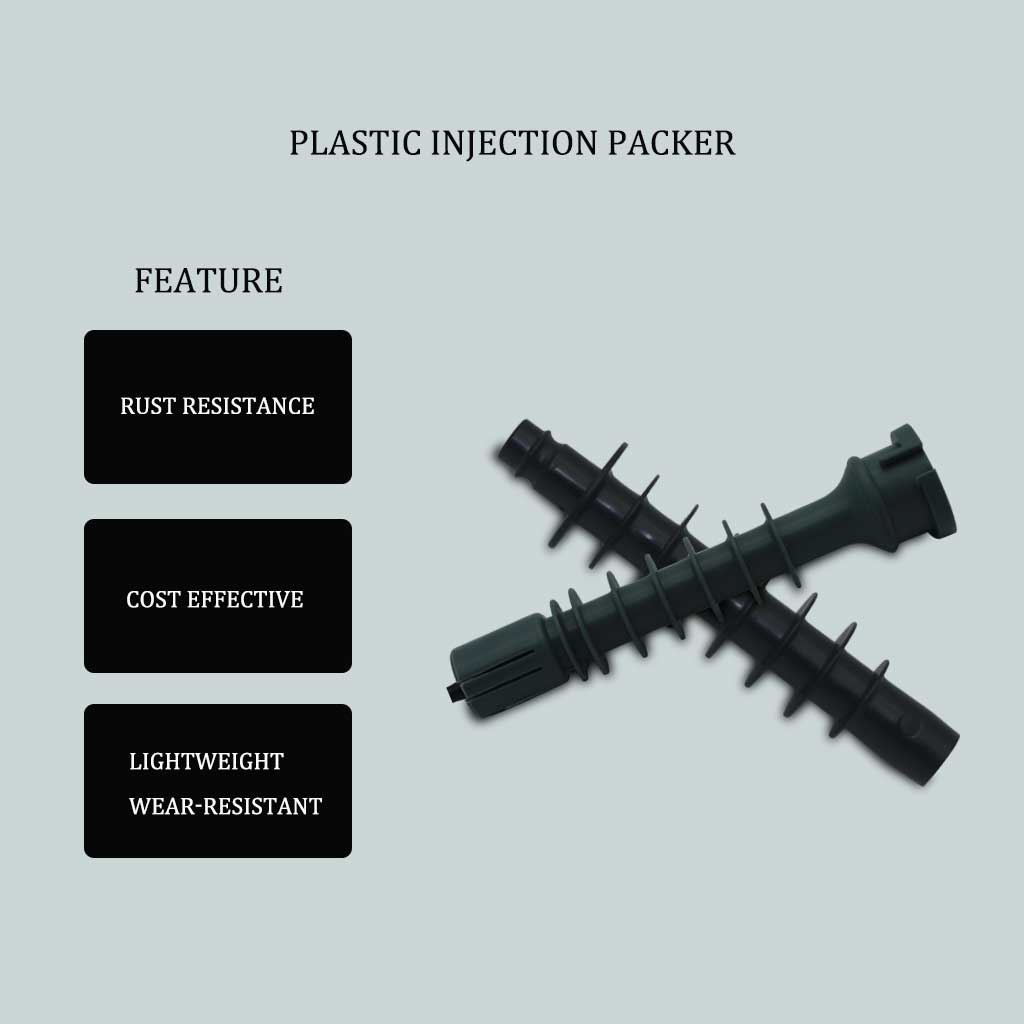

Plastic packer is apply for rapid injection

As a disposable construction consumable, plastic grouting injection packer are widely favored in the fields of building reinforcement, foundation treatment. Its core advantage lies in the large-aperture flow channel design, which perfectly adapts to the rapid injection requirements of high-viscosity slurries such as cement slurry, epoxy resin, and polyurethane.

Compared with traditional metal injection packer, plastic materials effectively avoid the risk of rust. At the same time, the tube body is injection molded with HDPE, which has both lightweight and wear-resistant. It can be discarded after a single operation, greatly simplifying the construction process and reducing maintenance costs.

The product is designed with multiple sets of annular protrusion structures on the pipe body, forming multiple technical advantages: first, the annular protrusion can be quickly connected with the grouting equipment to achieve a stable mechanical lock; second, the annular structure forms a physical barrier layer, which effectively inhibits the backflow phenomenon during the slurry solidification stage to ensure that the slurry fully fills the target area.

Adhesive injection packer apply for corner crack

The adhesive grouting injection packer uses interface bonding technology to achieve zero-damage concrete crack repair, which is different from other grouting packer. There are three main types of adhesive grouting injection packer: aluminum packer, plastic packer, and iron steel packer. The adhesive injection packer is easy to install and is mainly used for shallow crack repair. It does not require high pressure to grout epoxy resin and polyurethane, and will not damage the concrete structure.

The overall length of the adhesive grouting injection packer is short and can be installed and fixed at the corner. For cracks in some corners, the adhesive packer can play its advantages and ensure that the epoxy resin and hydrophobic polyurethane achieves maximum filling in the crack, which cannot be replaced by other grouting injection packer.

The adhesive packer is particularly friendly to DIY. It is easy to install and fix, and is suitable for repairing crack for home works also. There is no need to purchase a high-pressure grouting injection machine for use, which is economical and cost-saving.

Copper injection packer for small crack

In response to the needs of repairing microporous cracks in buildings, we have developed copper injection packer. The main copper packer series are 6mm and 8mm. By matching copper packer, the cracked construction can achieve uniform penetration of grouting materials, and truly realizing the modern construction concept of "minimally invasive repair".

After quenching, the copper tube reaches HRC42 hardness, with excellent wear resistance and deformation resistance. The surface nickel plating forms a double protective layer, so that the copper packer can still maintain long-term stable working performance in harsh environments such as humidity and saline-alkali. After using copper packer for non-destructive grouting, a large amount of secondary repair work is reduced compared with conventional processes.

Compared with other injection packer, the unique antibacterial properties of copper can effectively avoid microbial contamination of repair materials and extend the service life of the building repair system. It is particularly suitable for scenes with strict requirements on structural integrity such as historical building protection and fine decoration house renovation.

Summary of the grouting injection condition

In addition to the above popular grout packer, we also customize and provide a variety of injection packer to meet the application of grouting of different crack depths and different grouting flow rates. For example, the removable head type is a combination of multiple packer, which can not only check the slurry status, but also has the advantage of light weight.

Through the above introduction, I believe you have a deeper understanding of the purchase of waterproofing injection packer. When purchasing grout packer, you need to comprehensively consider the performance of the packer, evaluate geological conditions and grouting depth and other factors to choose the one that suits you best.

Choosing a suitable grout packer can not only make waterproofing projects easier and more convenient, but also improve work efficiency. Our company provides free working condition diagnosis services and provides a one-stop grouting waterproofing solution. Welcome to communicating with us any time.