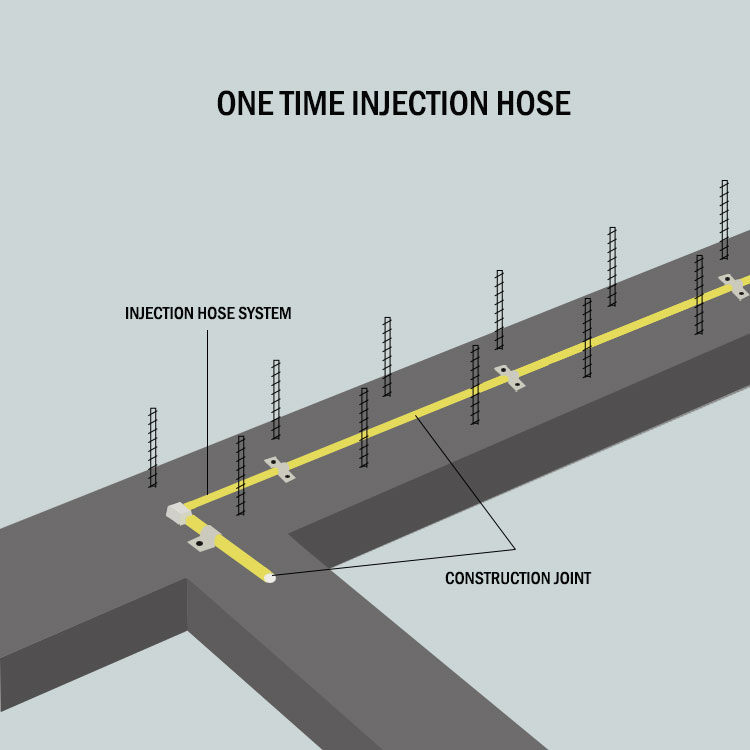

One time injection hose is pre-laying grout tube, which is using for concrete joint and junction waterproof sealing. In subways and tunnels underground, construction joints are easy to water leakage, thus multiple waterproof measures should be taken, such as fortification and comprehensive treatment. Embedding injection hose can easily, quickly, and effectively solve the problem of water leakage at construction joints.

The one time injection hose is a unique designed grout pipe tube. The injection hose is made of 3 layer, the inner is steel springs framework, the middle wrapped with non woven fabric cloth, and the outer is wrapped with nylon mesh.

The one time injection hose is a unique designed grout pipe tube. The injection hose is made of 3 layer, the inner is steel springs framework, the middle wrapped with non woven fabric cloth, and the outer is wrapped with nylon mesh.

High carbon steel have high strength and hardness, and it is corrosion resistance.

| C | Si | Mn | P | S | Cu |

|

0. 80~ 0.85 |

0. 60~0. 90 |

0. 12~ 0. 32 |

≤ 0. 025 |

≤ 0. 025 |

≤ 0. 02 |

Non woven cloth is wear-resistant, breathable and water permeable, friction resistance with good strength.

|

Equivalent diameter |

Tensile strength |

Elongation at break |

Elastic modulus |

Melting point |

Acid and alkali resistance |

|

18-48um |

≥500MPa |

10-28% |

≥3850MPa |

160~180℃ |

High |

The injection hose is 120m/roll, and have connection accessories.

8mm*12mm*120m

Note: Do not touch with steel bar, avoid damage the injection hoses.

Maintenance of water leakage from deformation joints and construction joints, and embedding of grouting channels for water sealing.

Metro engineering, tunnels, swimming pools and upstream parks, dams, ship locks, canals, reservoirs and ditches, nuclear power plants, primary and secondary cofferdam facilities, bridges, commercial and industrial buildings, underground garages, stadiums, aquariums, water tanks, and similar structures.